Expert

BITO XL Motion containers ensure quiet handling in the shuttle storage system at the fulfilment centre of expert Warenvertrieb GmbH

Our customer

expert SE in Langenhagen is a retail group specialising in consumer electronics, information technology, telecommunications, entertainment and household appliances. Like no other electronics retailer and true to the brand claim ‘With the best recommendations’, expert stands for the highest levels of service and consulting expertise. Expert products are available at more than 4,000 locations in a total of 22 countries. The various national member organisations are grouped together in expert International, which was founded in 1967 and is headquartered in Zug (Switzerland).

The merchandise distributor expert Warenvertrieb GmbH in Langenhagen is the operational centre of the group and offers the entire range of services and warehousing activities.

All expert specialist retailers are supplied from the new 13,000 sqm fulfillment centre which went into operation at the beginning of 2022. In the past financial year, expert retailers purchased around 50 per cent of their goods from the group's own wholesale organisation.

Initial situation and customer requirements

- expert was looking for a suitable container solution for the shuttle storage system in their fulfillment centre.

- The containers had to be suitable for automated small parts storage.

The containers had to be suitable for automated small parts storage.

Project brief

The BITO Solution

Automated small parts warehouse + XL Motion containers

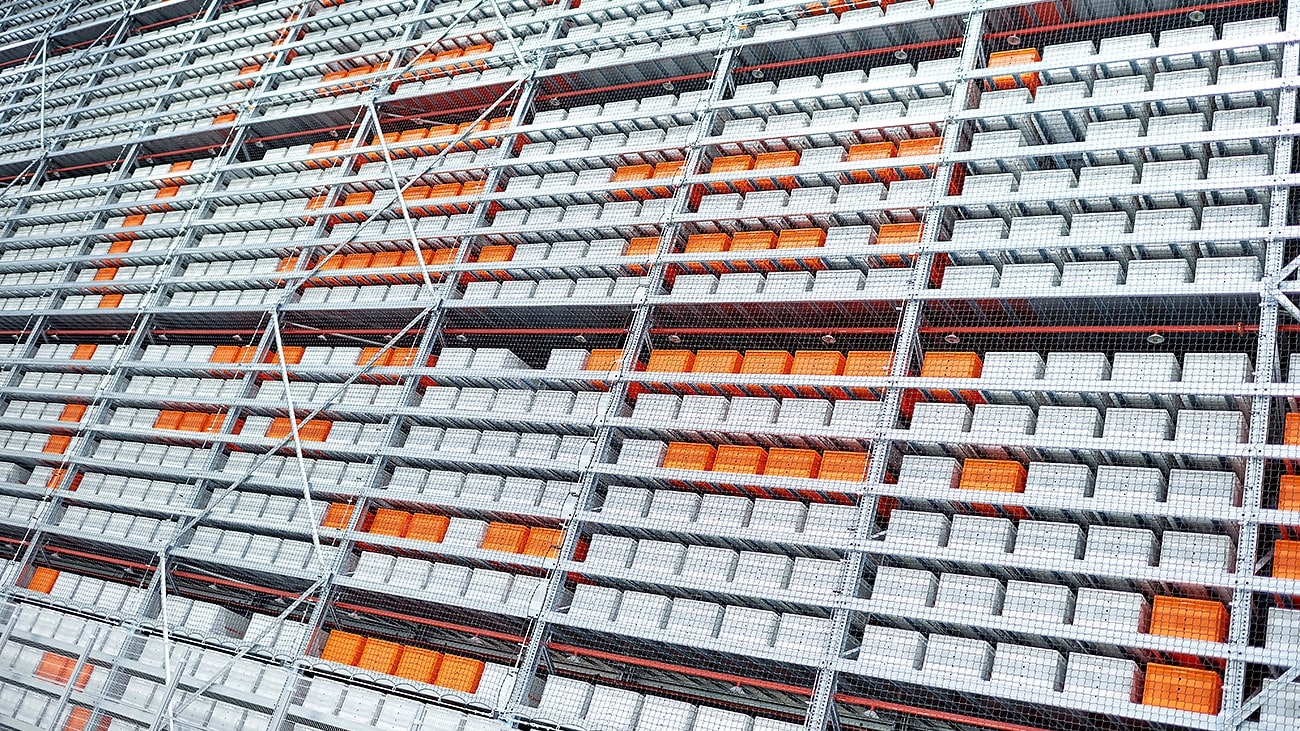

» In the shuttle-serviced small parts warehouse of their fulfilment centre, expert SE uses BITO XL Motion containers which have been designed as a classic container system for automated environments.

On-site application and key features of our storage solution

- A total of 46,000 BITO XL Motion containers are moved through the automated warehouse of expert Warenvertrieb GmbH.

- The containers are partitioned with dividers to accommodate expert SE's changing and varied product portfolio.

- Product labelling on the XL Motion Box has been standardised for automated use. The labels can be affixed in a slightly set-back area and are therefore well protected.

Customer benefits

In what way has the BITO solution helped our customer to realise their full potential?

- The specifically designed base and outer surface ensure that the BITO XL Motion container is extremely quiet on conveyor systems.

- The noise level in the fulfilment centre's shuttle-serviced warehouse has therefore been significantly reduced.

- The divider system for BITO XL Motion containers enables multiple subdivisions and offers unmatched flexibility.

"The BITO XL Motion container is a perfect product that exactly matches our requirements. Even in the initial phase of the sale, the support provided by BITO through constant dialogue was fantastic. When using the product, you realise how much engineering expertise has been put into the container series. Noise emission is "swallowed" by the base design, making automated container handling extremely quiet. In line with our product portfolio, the containers can be subdivided as needed. This offers us the greatest possible flexibility: it is no problem to expand our product portfolio or adapt to smaller batch sizes at short notice. Another ideal feature is that the box ID labelling system has been standardised for automated use. Labels are affixed in a recessed field and are therefore protected from damage. When it came to choosing containers for our new shuttle system, this was another plus point in favour of the XL Motion from BITO."