Ideal, for ...

- LIFO and FIFO storage

- Efficient space utilisation

- Increasing storage capacity and storage density

- Storing pressure-sensitive products

Do some of these points match your experience?

Read more or contact us directly on

02476 388852

The system

BITO pallet racking shuttle system is a deep lane/channel storage solution and a smart alternative to drive-in racking, push-back racking and pallet live storage.Shuttle vehicles are battery powered and are controlled by a radio remote control.

The shuttle carts run on rails in the storage lanes, loading and unloading pallets without human intervention.Once a task is completed, the shuttle returns to its original position at the beginning of the lane and can be relocated by a forklift truck.

The shuttle system can be used for storage in FIFO as well as in LIFO order.Shuttle vehicles can also be used for cold storage applications.

Your benefits

- Increased picking performance

» The shuttle drives into the lane instead of the truck driver. This reduces handling times and prevents racking damage.

- High degree of flexibility

» Compared to drive-in racking, where only entire bays can be accessed, shuttle-serviced racking allows access to each individual lane.

- Safety first

» Laser scanners in the storage lanes as well as in the truck aisle identify persons and obstacles. Combined with the BITO safety equipment for racking structures, shuttle systems ensure maximum safety at work.

- Safe product storage

» Shuttle handling prevents damage to goods due to rough handling and guarantees sufficient spacing between the pallets in a lane.

- Maximum utilisation of warehouse space

» Since there is no need for service aisles within a racking block, storage capacity can be increased by 60%.

- Scalability

» The shuttle system is scalable. This means that pallet throughput can be increased by increasing the number of shuttle carts. The system grows with your requirements.

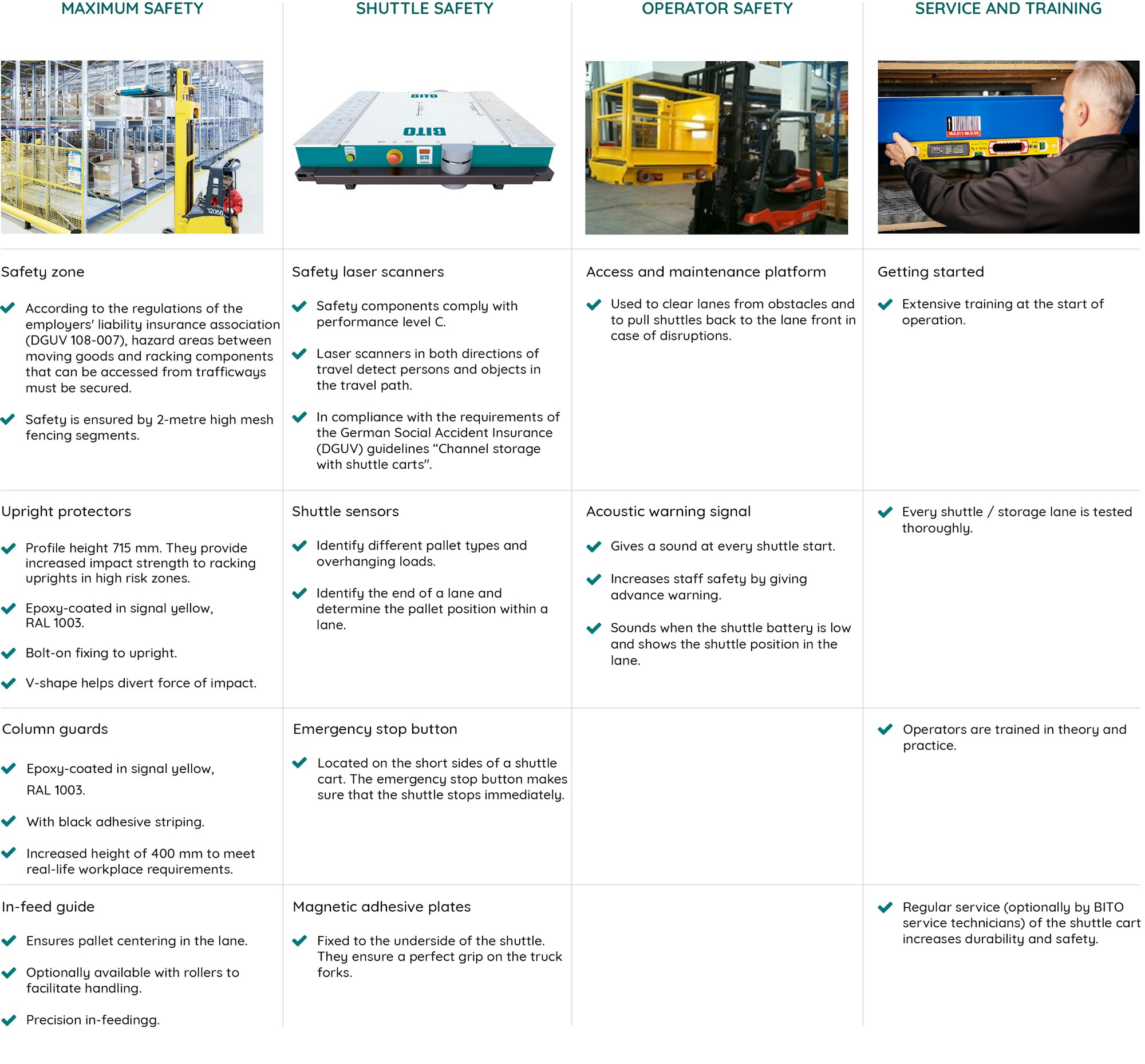

The BITO safety concept is based on 4 pillars:

Operator safety has top priority

People on the floor level of a racking block are at risk of being trapped between the shuttle and the pallet or the shuttle and the racking.Reasons for being in the racking might be, for example, floor cleaning or the removal of goods.

Technical features on the shuttle cart make sure that people are detected and that shuttles are stopped automatically and safely.For this purpose, we use safety laser scanners which safely stop the shuttle in case of danger.