Customer Requirements

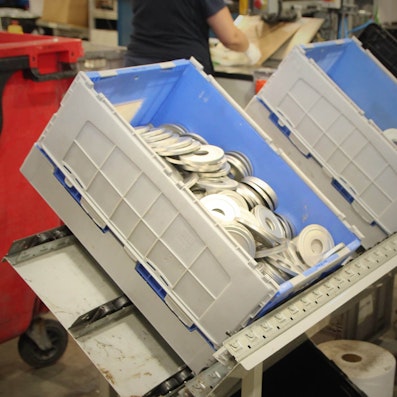

- Containers required to support a continuous flow of components between them and supplier.

- Components need to be protected in transit.

- Containers need to require minimum storage space when not being used.

- Eliminate the cost of disposing cardboard boxes previously used to transport components.

The BITO Solution

- Over 1500 EQ collapsible containers supplied, proving to be an excellent alternative to cardboard boxes.

- The containers' 20kg capacity and 285mm height meant they comfortably managed the components.

- When not being used, they collapsed to 75% of their volume meaning storage space required was low.

Storage facility features

- Continual flow of components through the facility

- EQ collapsible containers in a transit cycle between Parker and supplier

- Full containers wheeled on dollies to assembly area

- 3 full containers stored on sloping shelving in assembly area for picking

- When empty, containers are collapsed and stacked for return to supplier