Ideal if...

- You want to continuously supply your picking points with goods based on the goods-to-operator principle and need constant access to each product in your range.

- You want to achieve a high picking rate for a large number of small items.

- Given a relatively small surface area, you want to make optimal use of your available storage space using high bay designs.

- You want to organise your product range using modern management software.

Do some of these points match your experience?

Read more or contact us directly on

The system

Modern logistics centres, which need to manage a consistently high volume of orders, need storage systems which ensure constant availability of all items.

Automated small parts storage systems enable compact storage and fully automated supply of goods, allowing high picking rates for a large number of small items. The items are automatically moved along conveyors to the picker based on the goods-to-operator principle.

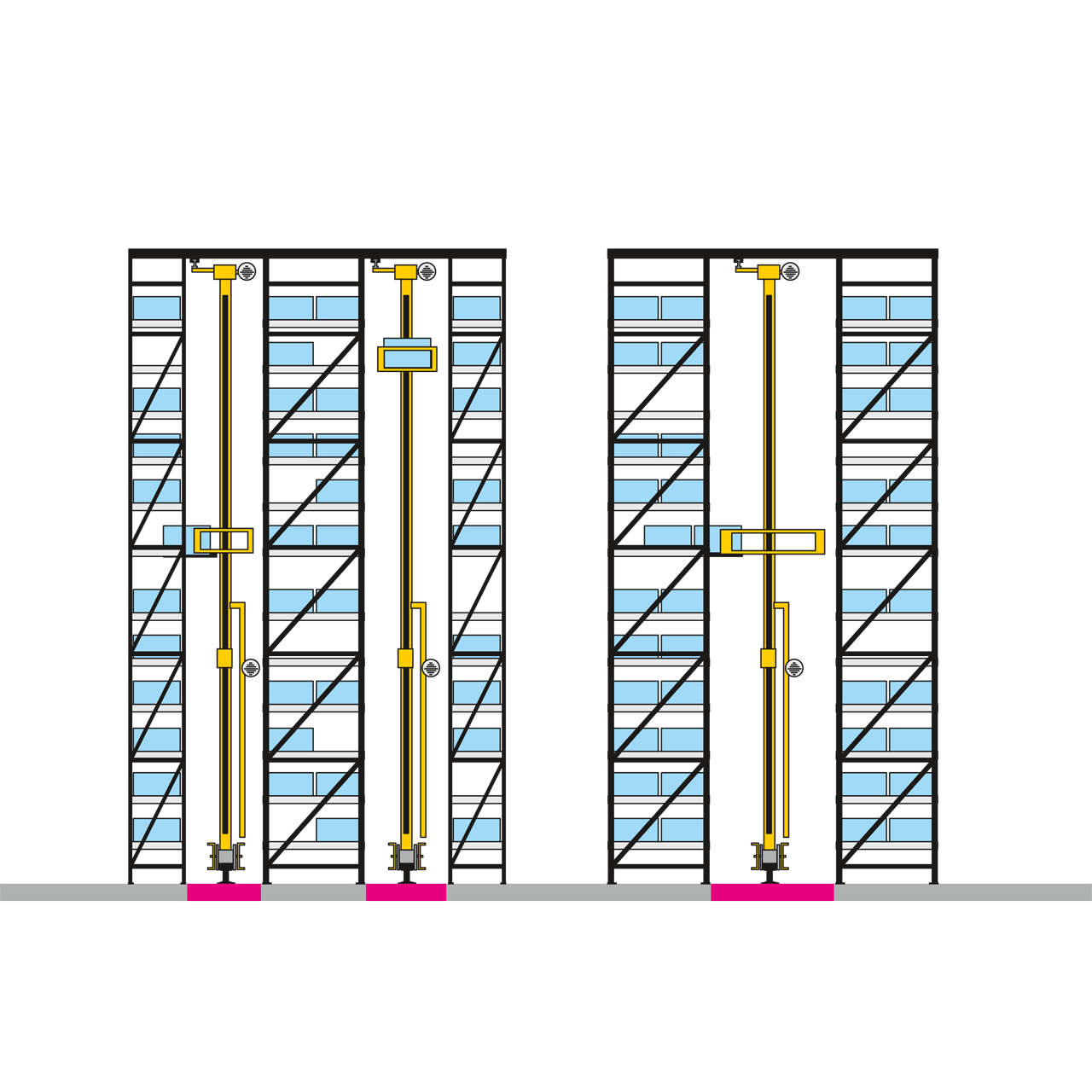

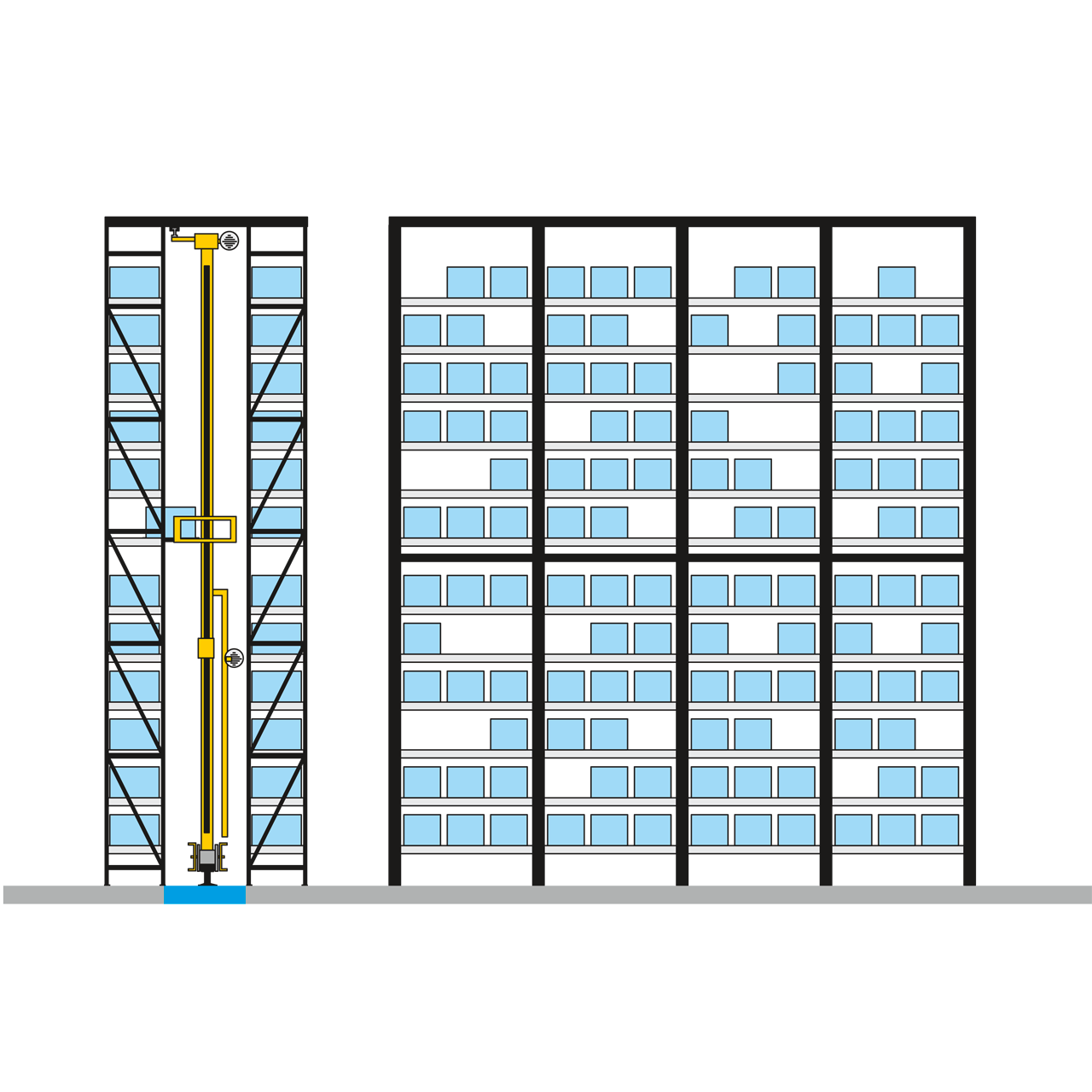

Depending on your turnover rate and load carrier type, this system is available as a single- or multi-position system and in a single-, double- or multi-tier design. Items are stored and retrieved using service vehicles.

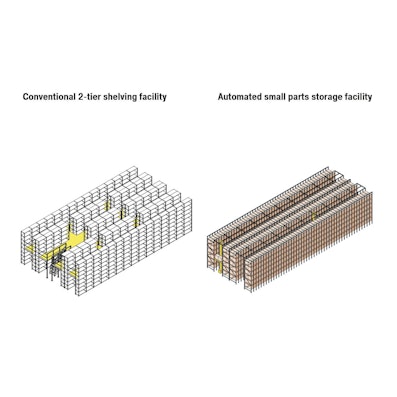

The high-shelf design means that an automated small parts storage system requires a relatively small base surface area. The state-of-the-art service vehicles move through exceptionally narrow lanes, which also increases the available storage area..

As a rule, automated small parts storage systems consist of a racking system with one or more lanes, a service vehicle, conveyors, small parts containers for storing and transporting goods, and the management software which ensures that the process remains organised and that individual items are always available.

BITO adjusts the automated small parts storage system to exactly match your space requirements, the weight of your stored goods, the picking plan and your product turnover rate. To ensure maximum system safety, BITO racks are produced in strict compliance with the narrowest finishing and assembly tolerances possible.

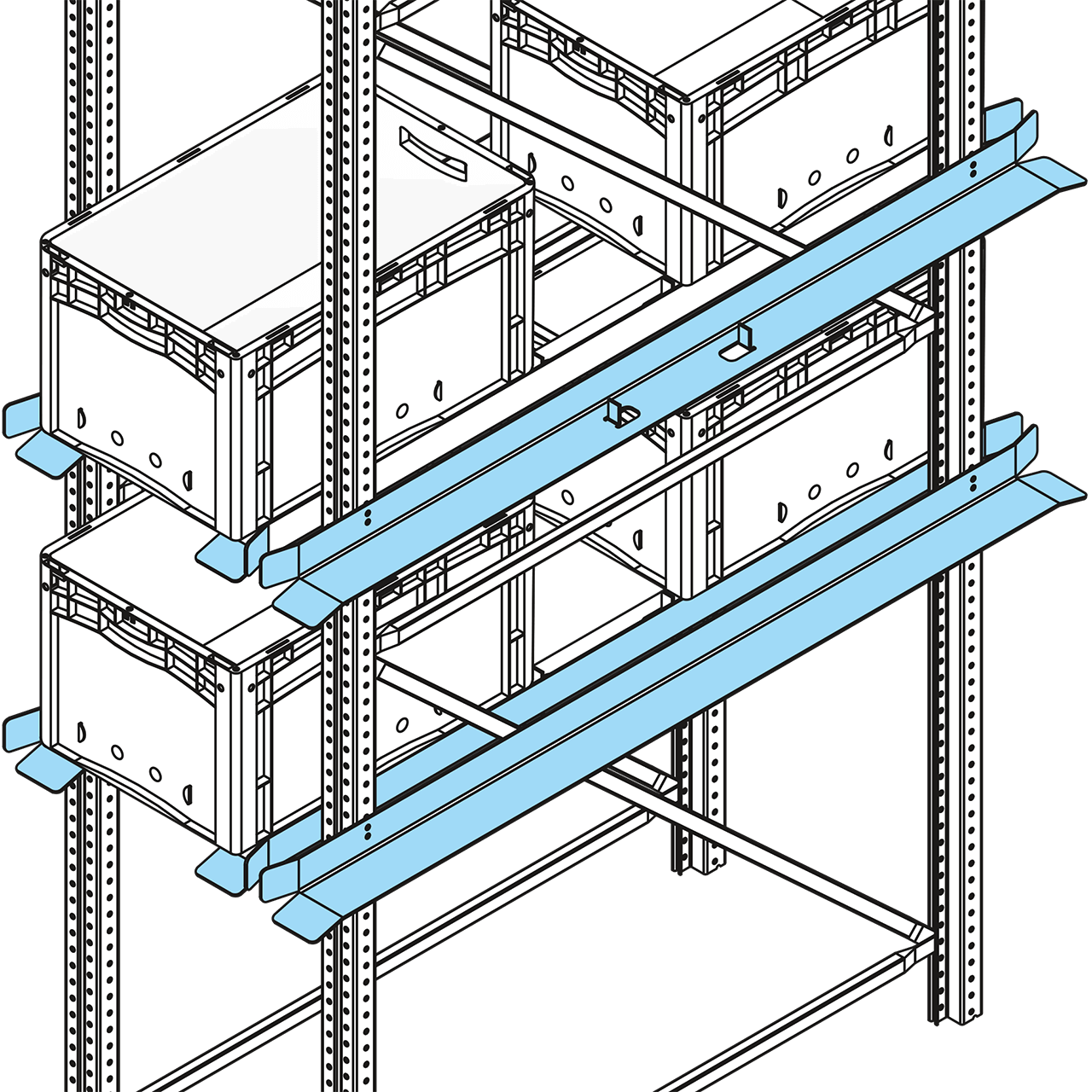

Single position system

Single-position storage is the most common system solution. In this system, each shelf has one container, tray or box stored on support bars (single or double deep).

Multi-position system

In this system, multiple containers or boxes are stored on each shelf single or double deep. Multi-position systems are often used for storage units of moderate individual weight.

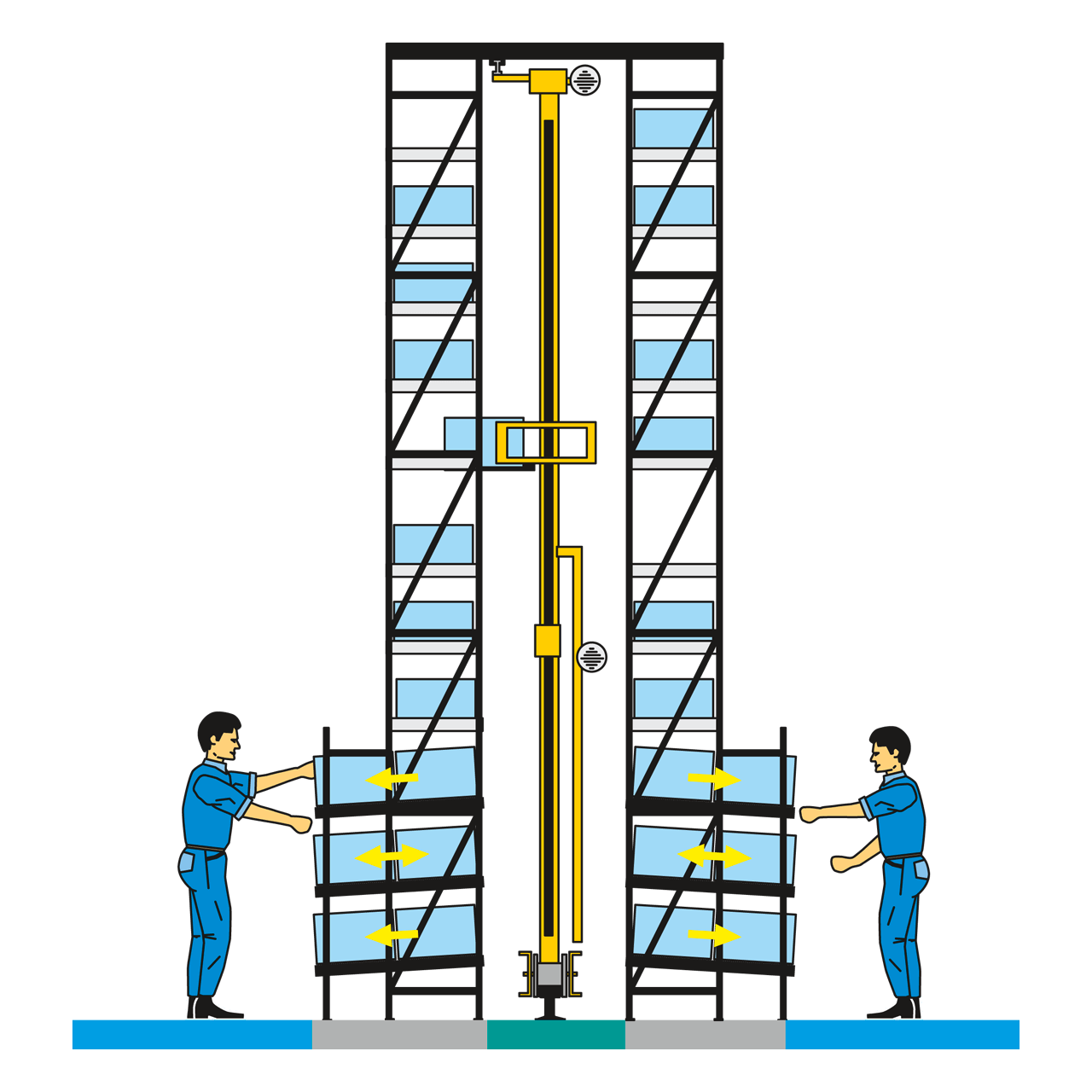

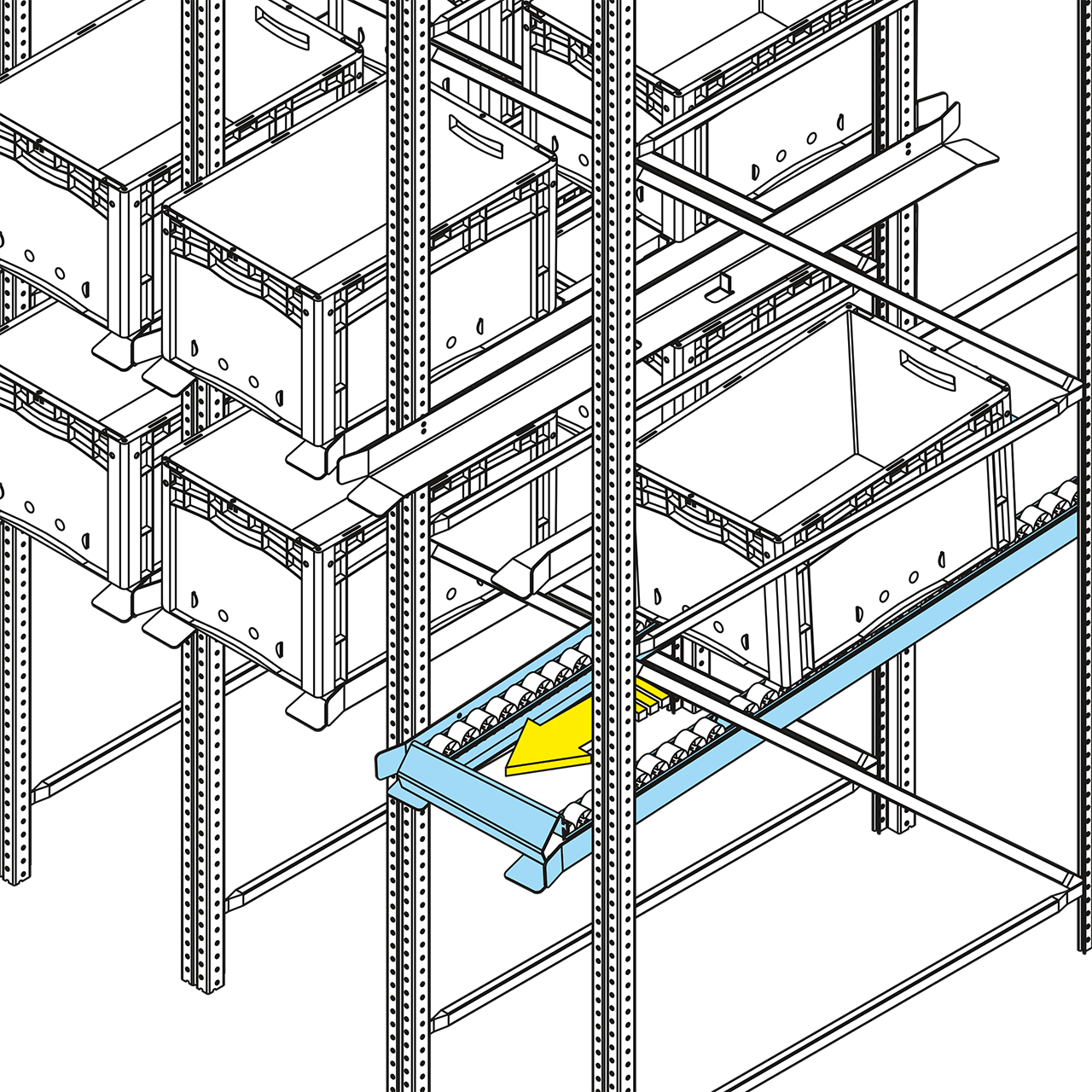

Integrated buffer stock

In automated small parts storage systems, materials are supplied on the bottom flow level. The buffer zone above ensures picking stations are constantly resupplied. The system can be designed as a single- or multi-position system depending on the weight and composition of the goods and the type of load carrier.

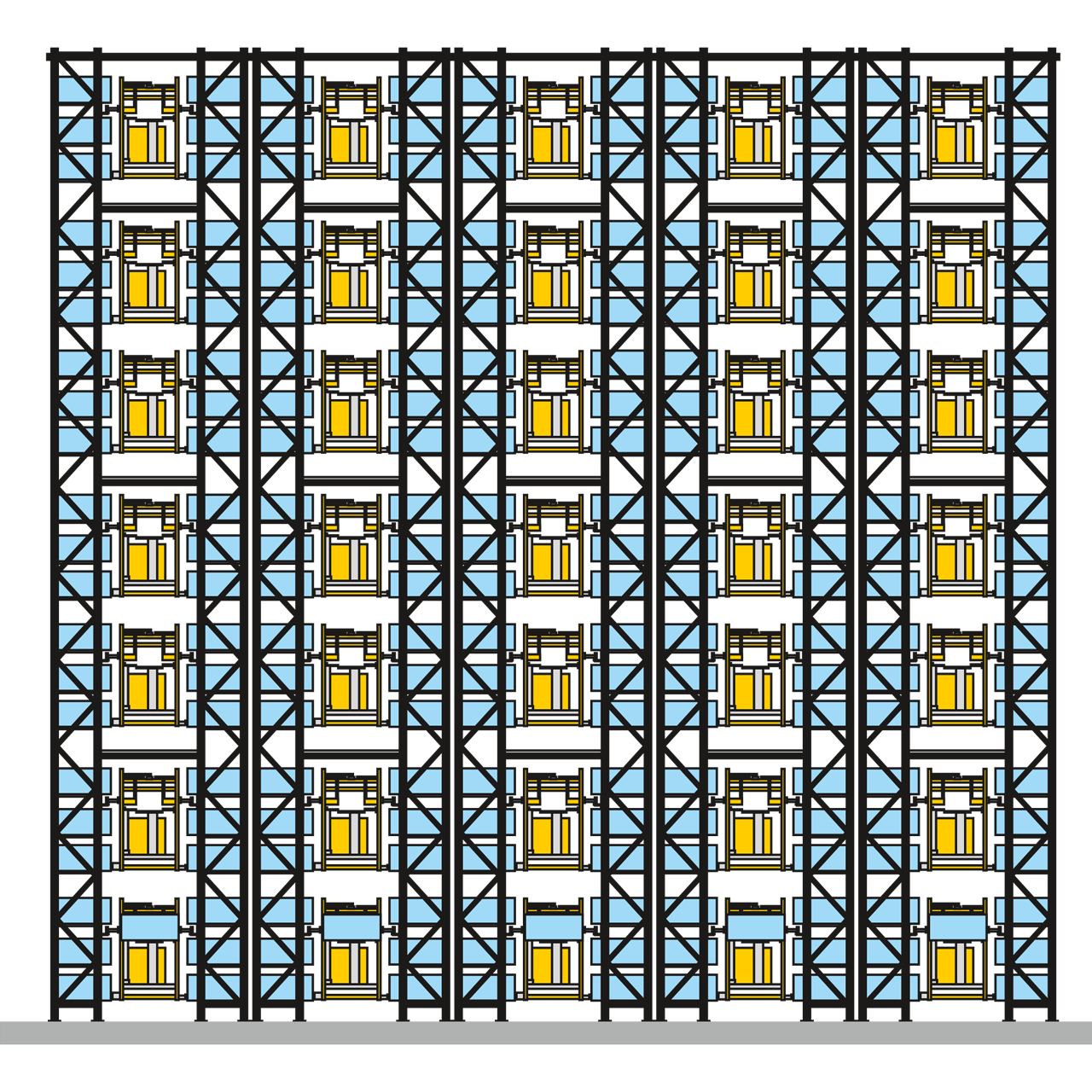

Shuttle solutions

Modern picking, distribution and consolidation warehouses are using shuttle systems more and more frequently. This high-tech, exceptionally dynamic solution allows you to multiply your goods turnover rate several times over. If multiple shuttles are used, the throughput rate increases correspondingly.

The benefits to you

General benefits

- Goods-to-operator principle

» The goods are stored in load carriers or moved along conveyors to the picking points. This eliminates the time taken to move, pick up and set down items, and access times are drastically reduced.

- Permanent inventory

» If the automated small parts storage system is integrated with a warehouse management software system, a permanent inventory of goods is guaranteed.

- Closed system

» Automation results in a complete redesign of the picking and storage area. This prevents unauthorised access to goods.

- Your single source supplier

» We develop and finish both the racking technology and the containers for automated systems. This allows us to precisely align all critical components needed for automated small parts storage.

High efficiency

- Save space

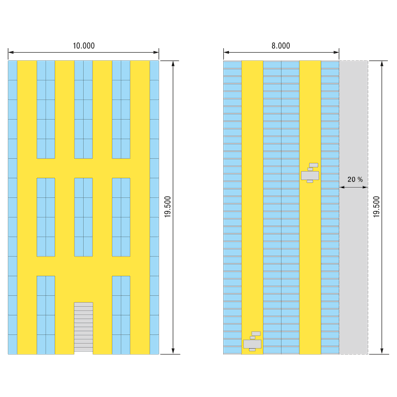

» Automated small parts storage systems occupy a significantly smaller surface area than two-tier standard shelving installations while maintaining the same number of container positions.

» In the example shown here, a standard container measuring 600 x 400 x 220 mm is used for reasons of clarity. Both a standard racking installation and an automated small parts storage system achieve a capacity of 3,700 containers.

» However, in the automated small parts storage system - unlike the standard racking installation - the containers are arranged double deep.

» The compact design means that fewer aisles are required and vertical space is used in full. As a result, the automated racking installation requires a surface area 20 per cent smaller.

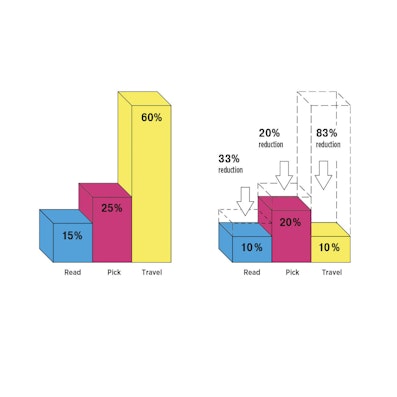

- Substantially reduced travel times

» The picking area in front of the automated small parts storage system is designed to be particularly ergonomic, giving a significantly clearer overview of the available selection. This results in enormous benefits when inspecting and picking items; travel distances and times are all but eliminated compared with a two-tier manual racking installation.

Components and options

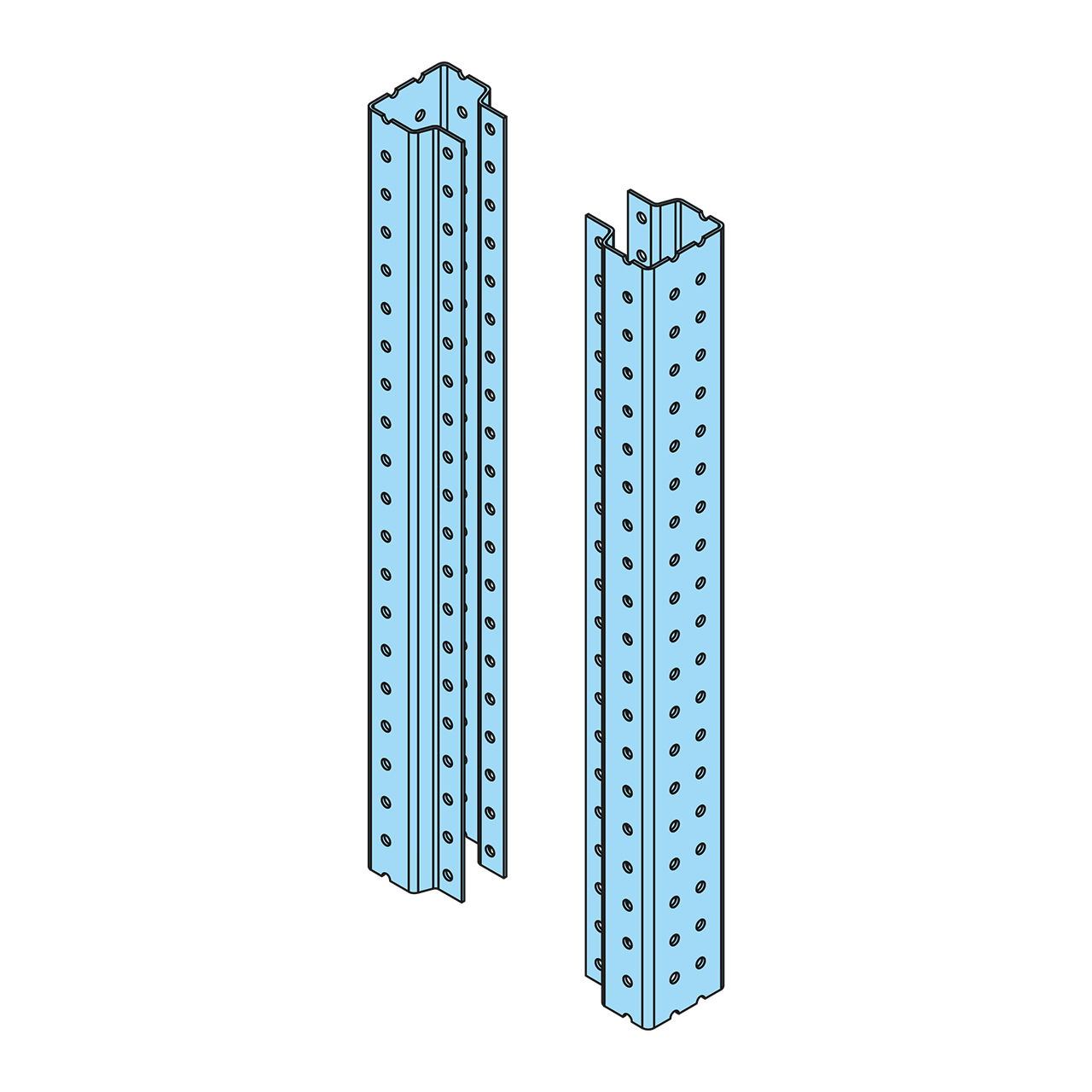

Frame

The system allows for frame heights of up to 25 mm. All frame components are riveted. Depending on the load and your requirements, frames are available in widths of 50 mm, 60 mm or 80 mm. The available surface area can therefore be used as efficiently as possible and storage capacity can be increased correspondingly.

Pallet support bars

The standard width of the angled support profiles for containers or trays is 70 mm. The angles can be secured at height intervals of 6.25 mm. The supports are generally equipped with a back stop; we define the material strength based on the load to be carried. For double deep or double-sided goods storage, we offer support bars with or without a middle stop, allowing you to safely set goods down.

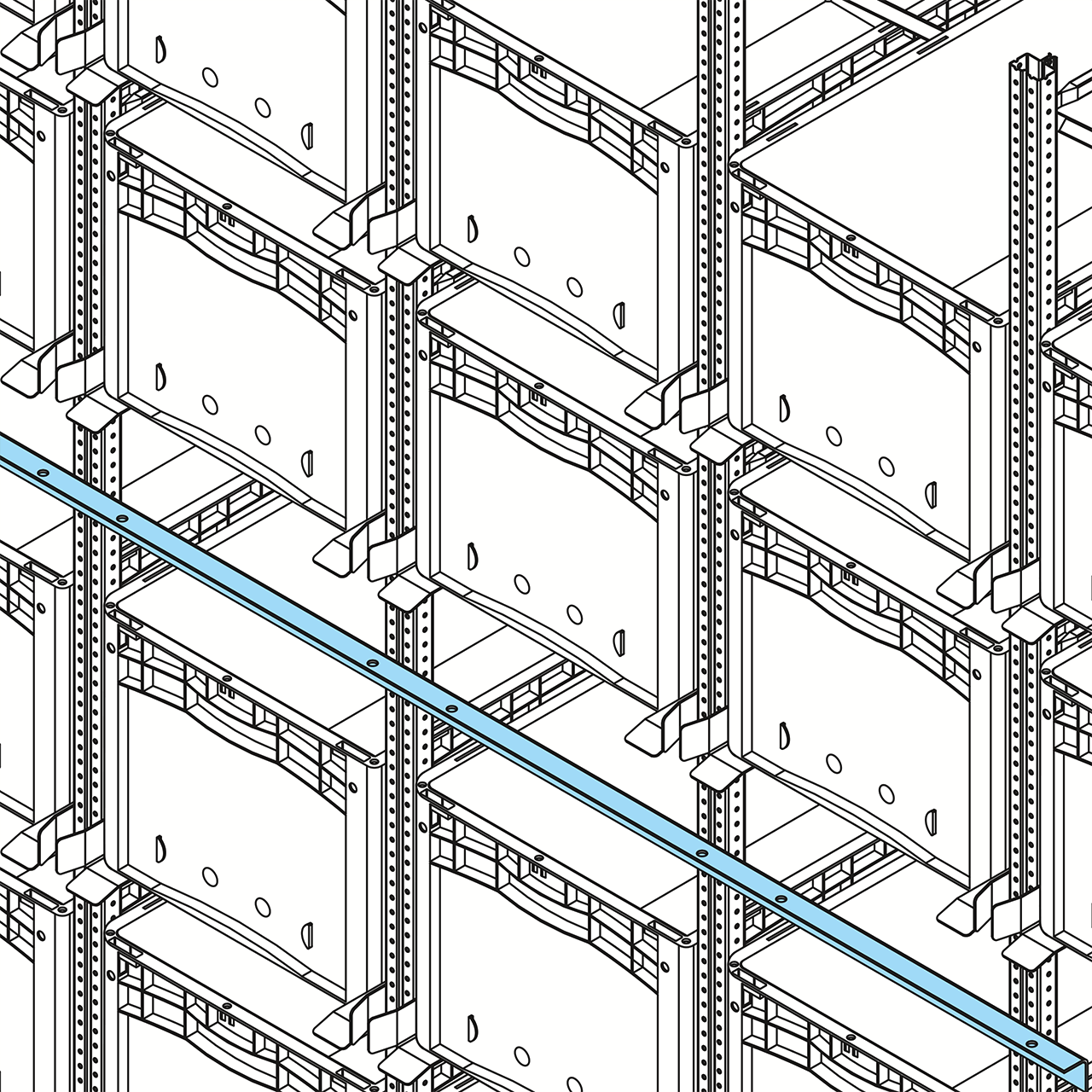

Bracing

Sufficient bracing with horizontal and diagonal struts is required for the precise functioning of the bin storage installation. Flat straps and galvanised steel sections are used for this purpose.

Feeder tracks

If the automatic storage installation is used to directly pick items from lanes, feeder tracks are installed at various positions on the rack for optimal routing. In these cases, angled support profiles will also be equipped with roller tracks of a length optimised for your exact needs.