Ideal if...

- You want your storage systems to be optimised for volume, space-saving and computer-controlled.

- You need a large buffer or reserve storage solution.

- You want to achieve constant item availability.

- You want to keep storage and picking error rates as low as possible.

- You value short order through lead times.

Do some of these points match your experience?

Read more or contact us directly on

The system

Automated pallet storage systems are typically fully automated systems. However, they can also be realised as partially automated solutions. These are usually used as buffer or reserve storage systems.

Implementing an automated system saves a great deal of time within a business’ logistical processes. Compared with a manual variant, automated systems produce clearly identifiable financial benefits, particularly when examining carton live storage, pallet live storage, and pallet racks. Automated solutions therefore represent a real alternative to manual ones.

In an automated storage system, throughput times are significantly shorter, picking and storage error rates decrease considerably, goods are always available and less floor space and storage volume are required. The computer-controlled system enables a permanently-available inventory.

As a closed system, automated pallet storage also has the advantage of helping to prevent unauthorised access to goods.

When designing our automated pallet storage systems, we work exclusively with reputable service vehicle manufacturers.

Your benefits

- Shorter order throughput times

» Turnover and picking rates are much higher in automated systems than in manual ones, meaning that order capacity also increases correspondingly.

- Low error rate

» In an automated pallet racking system, the entire logistical process is computer-controlled. This substantially reduces the error rate during storage and picking.

- Constant product availability

» The racks in an automated warehouse are constantly automatically replenished. This guarantees that all items are always available.

- gain in floor space and storage volume

» Despite holding the same quantity of goods, automated systems require much less storage space than manual ones. You gain floor space and storage volume while saving on pricey building costs.

Automated pallet live storage

- Continuous order picking - of complete pallet loads as well as of individual storage units

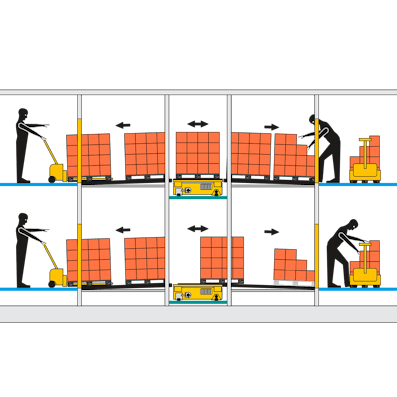

» In an automated pallet live storage system, pallets are stored with the help of a carriage (see diagram) or a lift truck. Loading is done automatically by a mobile feeder system. The picker always has a second pallet available in reserve. As soon as this reserve pallet has moved to the picking face, the buffer storage position - now empty - is immediately replenished.

To increase the available storage space, additional static storage zones above the aisles can be assigned carriages to make full use of vertical space. Alternatively, you can design the system with additional pallet live storage channels in mind, allowing you to store multiple pallets in a row.

» On the picking face, you can either pick from individual storage units or retrieve entire pallets using hand pallet or fork lift trucks.

» The roller conveyor section on the picking face is divided into three sections to allow you retrieve pallets using hand pallet or fork lift trucks. The space between the conveyors is fitted with drive-in plates, allowing the service vehicle to drive straight in.