Our customer

With a staff of 7,400 operating in 26 locations in 10 federal states, DMK is the biggest dairy company in Germany. The two merging companies Humana and Nordmilch, both with their roots in cooperative organisations, were already Germany’s largest milk processors. The post-merger company DMK processes 6.8 billion kilogrammes of milk supplied each year by around 8,900 dairy farmers into high-quality products. International trade organisations, food processing companies and wholesalers count among DMK's customers. The dairy processor provides a wide range of products covering several categories such as basic milk products and cheese, milk-based ingredients for food and drink manufacturers, baby food, ice cream and health products. Offering brands such as MILRAM, Humana, Biolabor and NORMI, DMK Deutsches Milchkontor is a major player in Germany and in 100 other countries and a reliable partner for traders and consumers.

Customer requirements

- Increase the available storage capacity by some 500 storage positions.

- Make better use of the available storage space at the existing premises to avoid the need for a new building.

- Provide ready-collated orders in a racking facility in the goods-out department in order to reduce throughput times.

- Enable mixed use of European standard pallets and H1 plastic pallets.

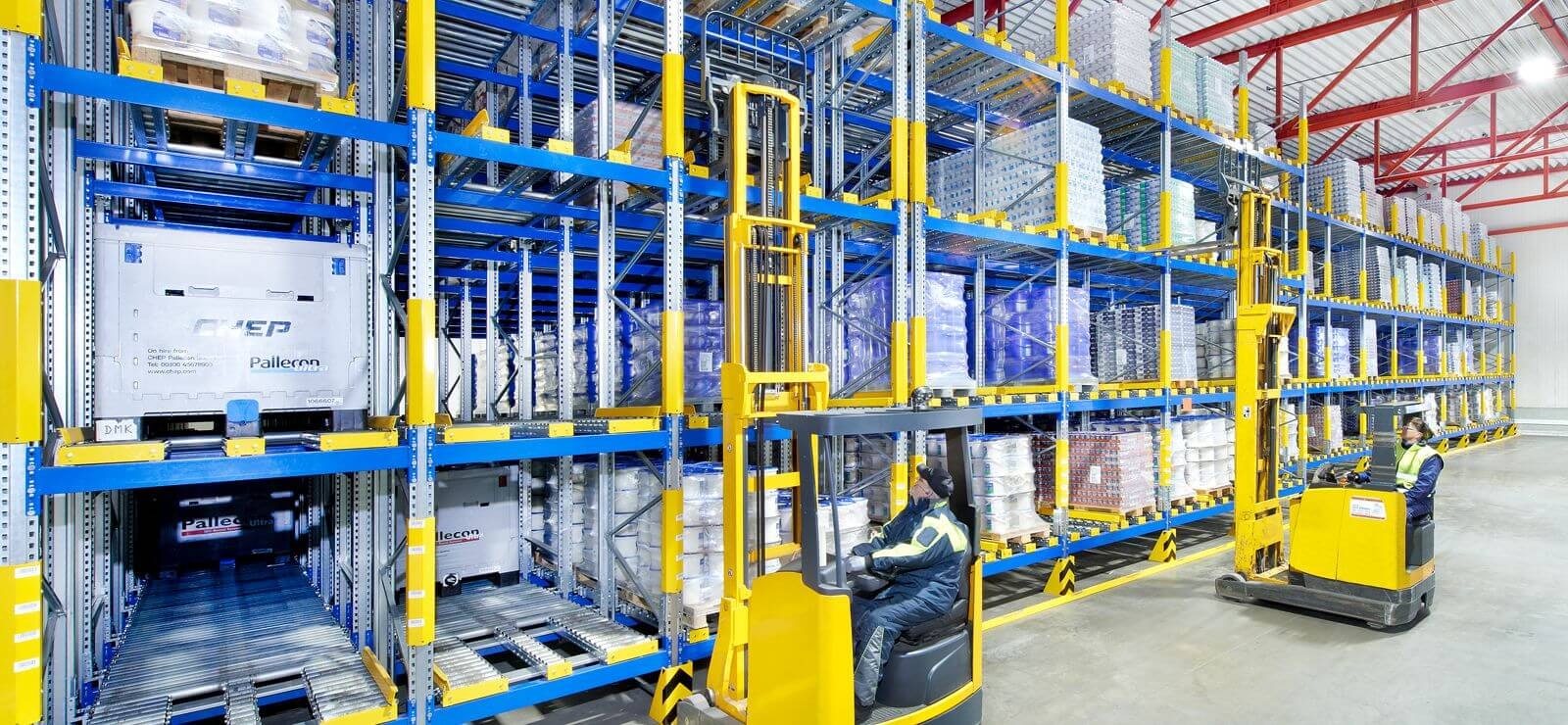

Storage facility features

- Goods that have already been produced are grouped into dispatch route related batches.

- These tour-related batches are provided for dispatch in pallet live storage racking right at the loading docks.

- FIFO stock rotation

- Goods on the floor level of the racking are used as “take away” supply: Drivers can conveniently pick their tour batches and load them into the lorry.

- Pallets can be retrieved with an electric hand pallet truck.

- The upper racking levels are used as a product buffer, thereby fully utilising the available warehouse height.

- The racking lanes feature full-width rollers and triple roller tracks to accommodate European standard pallets as well as H1 plastic pallets.

Customer benefits

- The requirement to increase storage capacity was met with a pallet live storage facility which makes excellent use of space.

- The customer did not have to invest money into a new building.

- Tour preparation is a lot more efficient now.

- Lorry waiting times are eliminated, since picked goods have already been collated by sort keys such as a customer number or the dispatch route.

- Read, travel and pick times are substantially reduced.