Shipment monitoring

- Real-time temperature and humidity monitoring

- GMP, GDP and MHRA compliant

- Hygienic storage and cold chain compliance

- GEO position tracking

Pharmaceutical supply chain safety and traceability

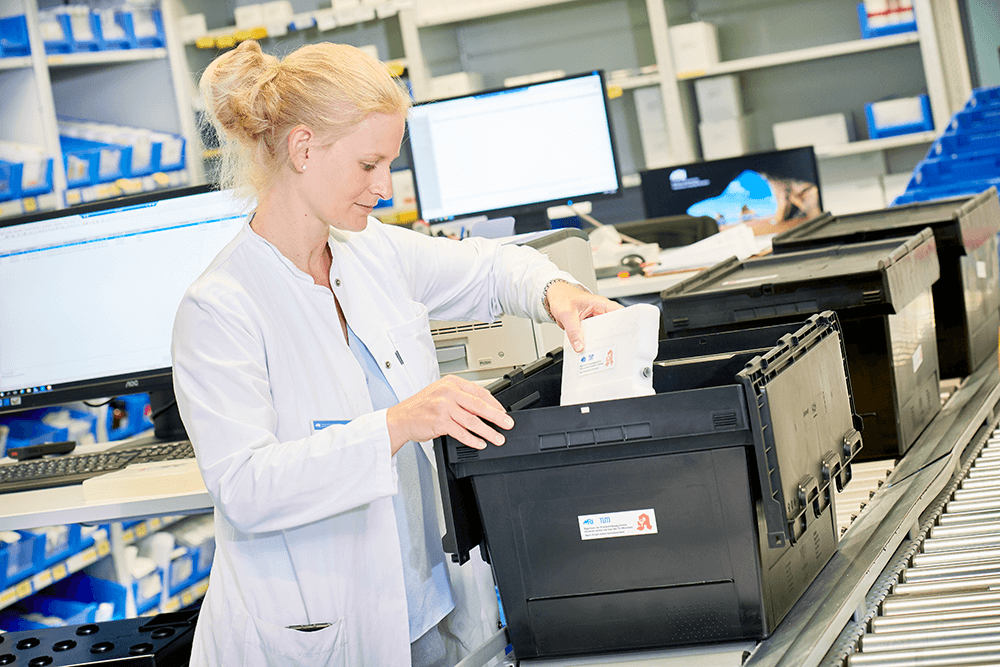

- Manual shipment monitoring: Place the beacon into the box to be shipped and read out data using the app

- Automated shipment monitoring: Place the beacon into the box to be shipped and read out data using the SmartHub at specific locations or in specific vehicles.

- Real-time monitoring and seal: Place the beacon into the box and fix the SmartHub device as a lock on top

In pharmaceutical areas, secure and seamless monitoring of ambient conditions are essential for product safety. Many products are temperature-sensitive and must be stored and shipped under special conditions. Shipping temperature-sensitive goods outside of climate-controlled warehouses must comply to guidelines and regulations that are intended to guarantee temperature monitoring over the entire supply chain. To meet these requirements, a temperature and humidity monitoring solution is necessary. Apart from distribution containers with thermal insulation, BITO also provides an easy-to-implement and smart tracking solution for shipment monitoring.

Temperature-sensitive products can be shipped safely without cold chain interruptions

This temperature monitoring system consists of a SmartHub device and Beacon data loggers and meets all the requirements of the pharmaceutical industry. In addition to monitoring temperature and humidity, you can use the system to monitor many other features, such as to control position, impacts and the geo-location of your shipment. Transport routes are more transparent than ever, as the system enables seamless documentation. As soon as deviations are recorded, a mail or SMS is sent to the person in charge in real time for instant rectification. This avoids additional costs due to damage and eliminates the risk that goods do not arrive in perfect condition at the customer’s premises.

The data is immediately transferred to the BITO Cloud and archived for later retrieval.

The device can be optimally integrated into the BITO PharmaBox lid and keeps your goods perfectly safe during shipment. The SmartLock locks the box and at the same time serves as a seal.

Here is why you should implement this tracking solution!

Optimal pharmaceutical supply chain monitoring

- Cloud solution enables real-time temperature monitoring - Data reporting tool exports reports to .csv and .pdf

- Can be used on an application-specific basis for shipping temperature-sensitive products and for monitoring warehousing conditions

- GDP and GMP compliant

- Designed for a temperature range from -200° to +80°C

- Encrypted data transmission, accessible only to authorised staff

- Independent of WLAN or other IT infrastructure

- The plug & & play system allows easy installation and use

- Bluetooth-based automated data readouts prevent interruptions in the cold chain

- Different temperature ranges can be covered (-78°C; 25°C to 15°C; 2°C to 8°C; +15°C to +25°C)

The system provides further monitoring solutions for your intralogistics and supply chain automation

Hospitals: In-house transport and data monitoring

In-house transport and storage of sensitive medications in hospitals are associated with extreme costs and a high safety risk. Drug cooling must also be ensured on the way between stations and in storage rooms. Temperature and humidity monitoring must comply with demanding minimum standards which require continuous data collection. Even minor temperature fluctuations during drug handling in hospitals can result in damage or loss of effectiveness. Detailed and reliable documentation of temperature and humidity data is therefore necessary.

Temperature monitoring of medical refrigerators

Until now, employees had to manually read and enter thermometer readings once or twice a day. This procedure is very labour intensive and error-prone. In addition, precise data analysis is impossible, as there are not enough measurements, i.e. reading intervals are too big. It is therefore not possible to tell how long a drug has been exposed to the wrong temperature.

The temperature monitoring system automatically generates, transmits and stores data, thereby bypassing all previous shortcomings.

Temperature monitoring in the pharmacy & during messenger service

Temperature monitoring and documentation in pharmacies is mandatory and clearly regulated by the pharmacy operating regulations (ApBetrO in Germany). This prevents that sensitive medications loose their effectiveness. In the case of medicinal and medical products, shelf life and usability are often only guaranteed under certain temperature ranges and physical conditions. In particular, medications requiring refrigeration can be damaged or lose their effectiveness even through minor temperature fluctuations. Suitable temperature monitoring in pharmacies aims at ensuring customer safety on the one hand as well as medicine safety on the other, to avoid financial losses due to damaged or disposed of pharmaceuticals because they can no longer be used.