Our customer

Sacchi Giuseppe S.p.A., founded in 1957, with the subsidiaries Comel, D.m.e. and DEMO, is one of the main Italian companies in the distribution of electrical equipment, lighting and industrial automation. For 60 years Sacchi has been working to offer a high quality service, providing the best products and solutions. 95 points of sale in Northern Italy, 2 consumer electronics megastores, a logistics centre and 1,350 people who work in synergy, with competence and professionalism, to respond efficiently and quickly to the needs of over 40,000 customers. In 2017 Sacchi became part of the international Sonepar Group.

The BITO Solution

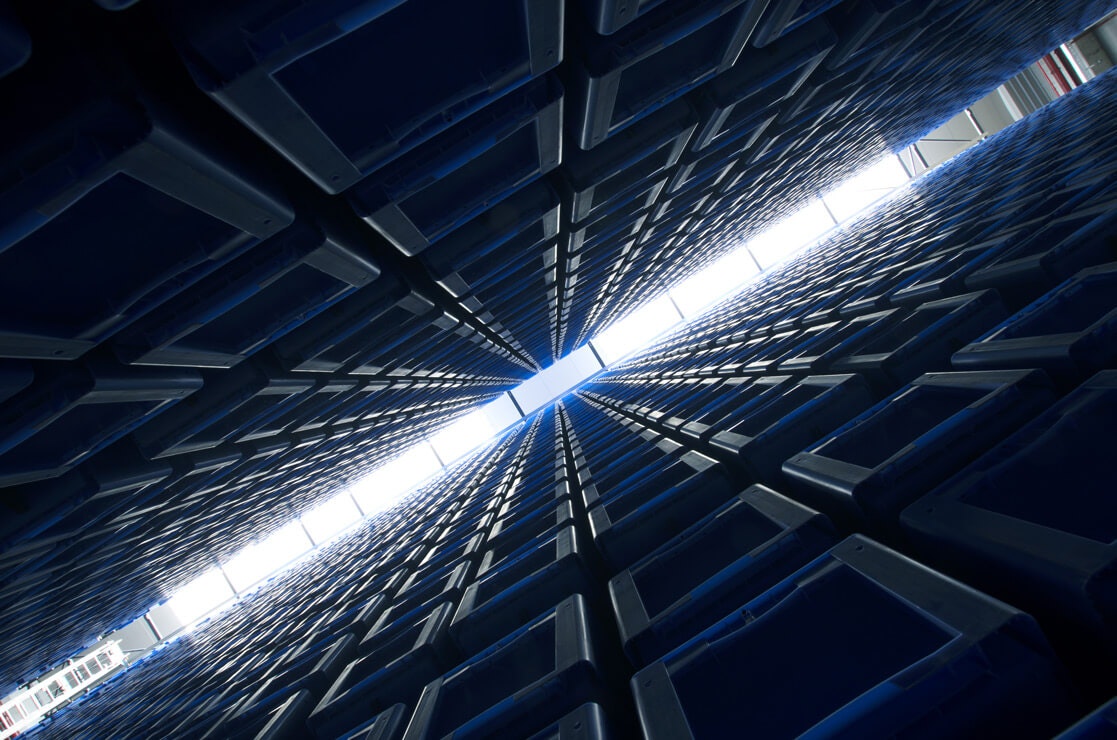

- Logistics management begins with the acceptance of incoming goods and material storage in the automated warehouse. The goods are stored in barcoded, single-reference BITO containers with dividers. The customer uses blue containers for material storage

- and green BITO containers for order picking. The operator receives the blue container at his workstation, from which he takes one or more references and places them in the green container for distribution.

- Once picking has been completed, the containers intended for customers will be sent to the packing area. Containers intended for restocking the points of sale are sent into the sorting area. In a final step, the containers are closed with BITO disposable seals and labeled for shipment.